Harvest to Bottle: Making Cider

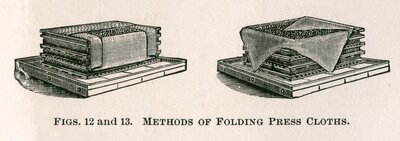

The cider making process has changed little in overall substance for centuries. The fruit is ground to a pulp, after which it is set in racks lined with a filter (typically cloth, in the traditional methods) for a press to force the juice out of the mass of ground fruit. The juice is then fermented; older methods would use wild yeast, while more modern techniques tend to use commercially available yeast strains that convert sugar to alcohol at predictable rates and volumes. From there, a host of different methods are used depending on the desired end result. The dry fruit mass left over after pressing – called pomace – can be used as a fertilizer, though research is ongoing in Dr. Olga Padilla-Zakour’s Lab at Cornell's Department of Food Science to reclaim tannins that escape the juicing process. (Photo of apple pulp filtering by Jason Koski)

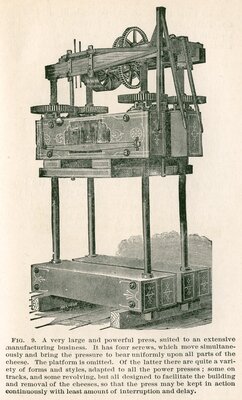

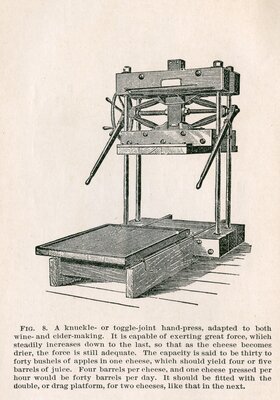

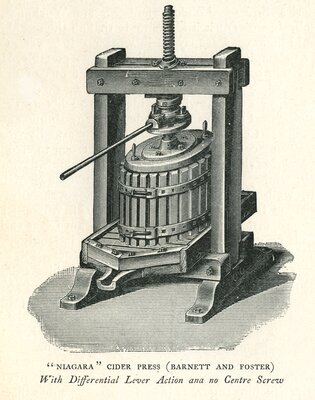

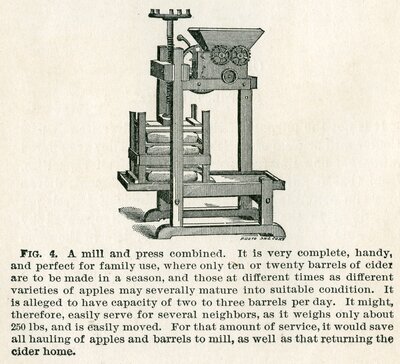

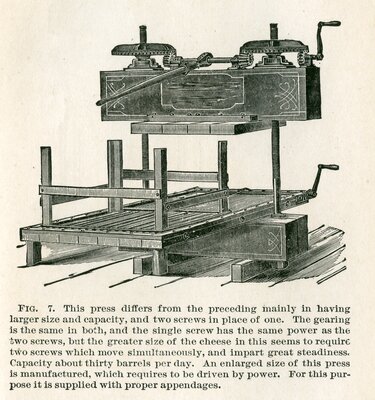

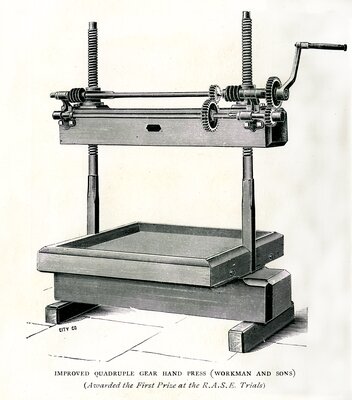

The engravings of cider making equipment below would not be foreign to workers in cider production today, despite being drawn over 100 years ago. Changes in materials, power sources, and efficiency may have entered the industry but the core process remains as it has for centuries - pulp, press, ferment, bottle.